Chave subminiatura no limpador de robô

Exactly how does an essential subminiature switch work in Robot Cleaner?

There is a subminiature switch on the robot panel to control its start/stop work. Ao mesmo tempo, it can also be controlled by remote control. The remote control can also be used to time the robot. The LCDs the timing countdown and the current temperature value in real-time.

What is a robot cleaner?

O robô de limpeza refere-se ao robô de varredura. Em breve, it will become an indispensable cleaning helper for every family like white goods. A comprehensive homebody is a wireless machine, mainly in the form of a disc. Use rechargeable batteries to operate; the operation method is the remote control or the operation panel on the device. Geralmente, you can set the time to make an appointment to clean and recharge yourself.

There is a sensor in the front that can detect obstacles. It will turn on its own if it hits a wall or other barriers. It will take a different route according to the settings of each manufacturer and plan to clean the area. (Some earlier models may lack some functions) Because of its simple operation function and convenience, it has gradually become popular, becoming a common household appliance for office workers or modern households.

Robotic technology is becoming more and more mature nowadays, so each brand has different research and development directions and has unique designs, such as double vacuum cover, attached hand-held vacuum cleaner, dust box that can be washed and mopped, can put fragrance, or It has functions such as photocatalyst sterilization.

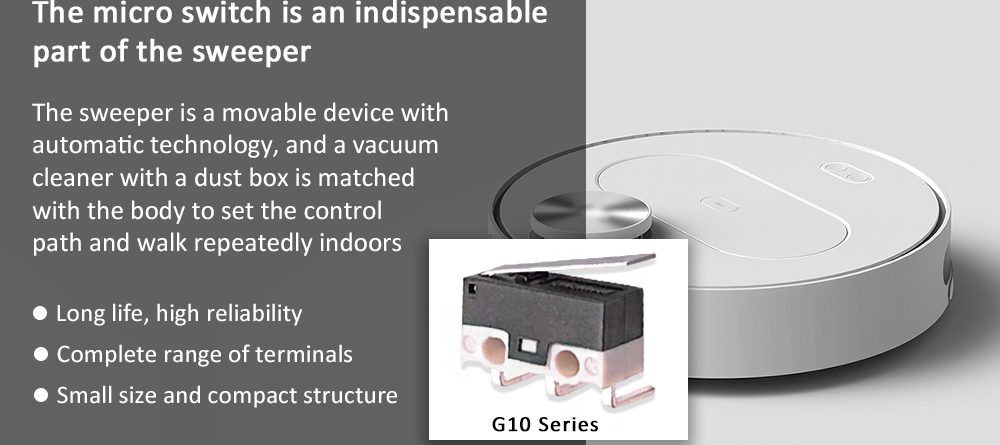

Subminiature switch in robot cleaner

Our Unionwell G10 Series of subminiature switches are widely used in robot cleaners.

G10 series Subminiature Switch Recursos:

- Tamanho pequeno e estrutura compacta

- Vida longa, alta fiabilidade

- Complete types of terminals

- Equipped with various types of operating handles

- Amplamente utilizado em eletrodomésticos e campos de controle industrial.

The G10 Series subminiature micro switch parameters are as shown in the following table:

| Avaliação | P1 | 0.1A 48VDC/125VAC(Banhado a Ouro Opcional) |

| 03 | 1A/3A 125VAC | |

| Frequência de operação | Elétrico | 10~30 ciclos/minuto |

| Mecânico | 120 Ciclos/minuto | |

| Contato de resistência(valor inicial) | 100mΩ Max (Depende dos P/Ns) | |

| Resistência de isolamento | a 500 VDC,100MΩ Min. | |

| Rigidez dielétrica | CA 600VAC RMS (50-60HZ) | |

| Temperatura de armazenamento | -40° C ~ + 85 ° C | |

| Umidade de Armazenamento | 85%RH Max | |

| Terminais de PCB retos de microinterruptor miniatura com êmbolo de pino | Elétrico | 6,000 ~ 100,000 ciclos(Depende dos P/Ns) |

| Mecânico | 1,000,000 Ciclos | |

| Peso Líquido Unitário | About 0.5g(Straight PCB Type Without Lever) | |

Lista de produtos de microinterruptor subminiatura da série Unionwell G10 >>

The suggestions for the subminiature switch option

Começar com, precisamos entender o layout do circuito e o requisito de classificação para o microinterruptor. Por exemplo, em muitos países europeus, a voltagem é 220VAC, então precisamos usar um interruptor que pode chegar a 220V no mínimo. Para ver se são apropriados, usamos um interruptor de 250VAC normalmente. A corrente elétrica coincide com as coisas.

em segundo lugar, qual código de circuito você precisa? Eles geralmente estão fechados ou geralmente abertos? Que depende do estilo do seu engenheiro.

Terceiro, qual operação você precisa? Você pode precisar considerar se eles são à prova d'água ou não à prova d'água, como eu sei muitos deles não são impermeáveis.

Em última análise, o credenciamento. Suponha que uma instalação de fabricação possa exigir os certificados para o microinterruptor. Por exemplo, A Europa exige ENEC, América e Oceania precisam da UL, A Ásia precisa de CQC, e assim por diante.

Robot cleaner working principle

The body of the sweeping robot is a portable device with automated technology. It is matched with a vacuum cleaner with a dust box to set a control path and walks indoors repeatedly, such as edge sweeping, centralized sweeping, random sweeping, straight expansive, etc. Path cleaning, supplemented by side brushes, central main brush rotation, rags, etc., enhances the cleaning effect to complete the anthropomorphic home cleaning effect.

Robot cleaner overall structure

The sweeping robot is mainly composed of the following parts.

Ontology: The brand design of different manufacturers will have other appearances.

Rechargeable batteries: Ni-MH batteries are generally used; some use lithium batteries, but the unit price of lithium batteries is usually higher. Each manufacturer’s battery charging time and use time are also different.

Charging stand: It can allow the robot vacuum cleaner to go home and recharge by itself.

Dust box: Different from the paper bag method of general vacuum cleaners, dust boxes collect dust.

There are roughly two types:

- Central dust box

- Placed in the rear dust box

Remote control: It is used to control the robot vacuum cleaner and can also be controlled on the body.

The sweeping robot mainly includes the following parts:

- A walking driving wheel and driving motor: This part mainly ensures that the robot can move in the plane. Infrared switches are installed on the front and side of the housing as collision detection sensors. The three infrared switches on the bottom step detection sensors prevent falling. The drive wheel is equipped with a photoelectric coding disk, which can detect and control the wheel speed and perform positioning and path planning. Ao mesmo tempo, the ultrasonic sensor has been expanded to meet the needs of precise positioning;

- Cleaning mechanism: The two cleaning brushes are driven by the motor so that the left side of the cleaning brush rotates clockwise and the right side rotates counterclockwise so that the dust can be concentrated at the suction port when cleaning the dust, preparing for the work of the sweeping mechanism;

- Floor sweeping mechanism: Create powerful suction to suck dust into the dust storage box;

- Floor scrubber: After cleaning and sweeping the floor, use the cleaning cloth installed under the shell to wipe off the fine dust remaining on the ground to ensure the quality of the cleaning work.

Primeiramente, The robot uses all kinds of sensors installed to obtain basic information about the indoor environment and itself, such as the location of obstacles, the distance it has traveled, etc.;

Then according to the obtained data, the corresponding control strategy is selected;

Last, through the control with the single-chip microcomputer as the core, The system performs obstacle judgment, obstacle avoidance strategy selection, and exercise walking implementation.

Classification of the robot cleaner

1,Single suction

The single suction cleaning method helps float ash on the ground. Ainda, it is not ideal for cleaning the ash accumulated under the table and the dust adsorbed by static electricity. (The design is relatively simple and only has one suction port)

2.Middle brush wafer type

It has a better cleaning effect on large particles and carpets, but it has a slightly poorer treatment of ground dust, which is more suitable for the home environment of European carpets. For the Asian market, the marble-headed floor and wooden floor are poorly cleaned. (The main surface of the cleaning method is a rubber brush, and a brush rotates relatively to pick up the garbage)

3.Brush cleaning system

Take the Taiwan model as a representative. It adopts the lifting V brush to float and clean, better fitting the comprehensive system to the ground environment. The electrostatic adsorption of dust on the surface is more in place. (The V-brush system as a whole can automatically rise and fall and form a negative vacuum pressure in the triangle area)

Features of the sweeping robot

- Sweeping saves time and effort, improves work efficiency, and improves energy efficiency: The cleaning process does not require human control, reducing the burden of human operations. People can use the time saved to do other meaningful things.

- Low noise: less than 50 decibels and the process of cleaning the room is free from noise.

- Air purification: built-in activated carbon to absorb harmful substances in the air.

- Lightweight and compact: Easily clean dead corners that ordinary vacuum cleaners cannot clean.

The workflow of the robot vacuum cleaner

- Função de microinterruptor O microinterruptor é um mecanismo de contato com um pequeno intervalo de contato e um mecanismo de ação rápida e um mecanismo de contato que realiza a ação de comutação com um.., you can start the cleaning robot through the keyboard or remote control and allow it to begin cleaning.

- Once the robot starts to work, it controls the cleaning mechanism to clean, the sweeping mechanism begins to sweep the floor, and the wiping agent starts to wipe the floor.

- The sensor detection module continuously collects external information when the robot starts to work. It sends it to the CPU for analysis and decision-making to generate the path of the robot’s walking.

- When the path planning requires the robot to perform the steering, the CPU changes the speed of the left and right wheels, respectively, and recognizes the steering through the differential speed.

- The robot can display related information (such as work mode, timing, or temperature) through the LCD during work.

- In addition to controlling the start and stop of the cleaning robot, the remote control can also time the robot to start working after a certain period or stop working after a certain period.

Why choose Unionwell subminiature micro switch China manufacturer?

Huizhou Unionwell Sensing & Control Electronics Co., Ltd specializes in producing quality micro switches for the automotive industry and white goods of home appliances. Os principais produtos incluem microinterruptores básicos, interruptores à prova d'água, pressostatos de ar, interruptores de teclado mecânicos, e interruptores de porta.

Para melhores preços, tempo de espera, e garantias de controle de qualidade, we acquired Huizhou Greetech Electronics Co., Ltda em 2021. Tornamos nossa base de produção na China com mais de 500 funcionários e um 250 capacidade de produção milhões de peças/ano.

With the subsidiary sales branch Guangzhou Unionwell Sensing & Control Technology Co., Ltd founded, nosso alcance global abrange a América do Norte, Europa, Ásia, e América do Sul.

A maioria dos nossos parceiros de negócios/clientes finais são globais 500 empreendimentos, incluindo marcas mundialmente famosas de eletrodomésticos e fornecedores automotivos líderes na América do Norte e Europa.

We are launching a new industrial base at Longmen, Huizhou, Província de Guangdong, que funcionará como sede da Unionwell. Equipamentos de automação serão introduzidos, melhorando maciçamente a capacidade de produção de interruptores de 250 milhões de peças para mais 1.3 bilhões de peças/ano.

Para mais microinterruptores, visite nosso site oficial: https://www.unionwellswitch.com/.

Enviar um email: inquir@unionwellswitch.com.