Pressure Switch : How They Operate

Pressure Switch Introduce

A pressure switch is a unit that works an electric call when a pre-specified liquid pressure is reached. The change makes an electrical call on either pressure rise or stress fall from a specific pre-specified pressure degree.

Stress switches are in various industrial and property uses like air conditioning units, well pumps, heating systems, etc.

Review our pressure switch sign article for more information.

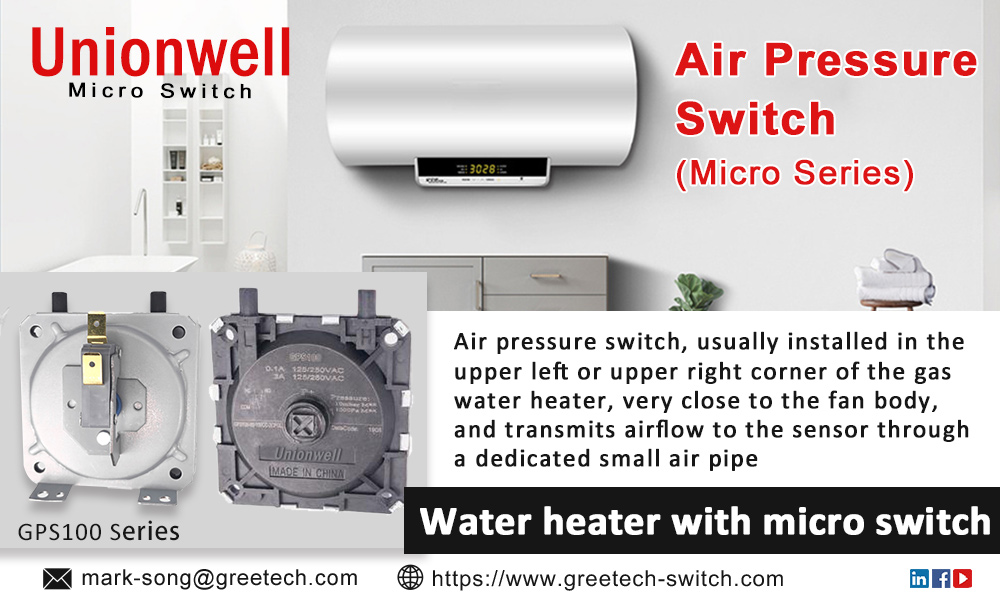

Unionwell GPS100 Series Air Pressure Switch Products List >>

A pressure switch should certainly not be baffled along with a stress transducer. A stress transducer converts pressure into a power output signal.

All tension switches types

- Low-pressure switches

- High-pressure switches

- Digital pressure switches

- Vacuum cleaner pressure switches

- Converter pressure switches

- Effectively push pressure switches

Mechanical pressure switch

A technical pressure switch uses a springtime and a diaphragm, or engine, to regulate at what pressure the micro-switch is caused. The spring season is the opposing force to the inlet tension, and the spring’s pretension is readjusted with a set screw or even button.

The springtime allegation directly correlates to the pressure the change helps make an electrical get in touch with. When the pressure falls, the change resets to its original state.

The difference between the change aspect and the reset point is called hysteresis. Commonly this is conveyed as a percent of the switch point market value, for example, 20%. The manufacturer specifies the hysteresis, which is undoubtedly not configurable for most mechanical buttons due to the customer.

These tension changes commonly have three various sorts of contact:

- ordinarily open (NO)

- ordinarily shut (NC)

- Alteration (SPDT) calls.

Alteration calls are for each NO and also NC operation.

The technical pressure switch is much better for handling high voltages and amperages than an electronic pressure switch. They could be used to create a contact improvement for an increase or even lower stress.

Electronic pressure switch.

A digital pressure switch uses an electrical pressure sensing unit to gauge the improvement in inlet stress. They have digital display screens to set up the changing function. The switch point can be supplier set or scheduled on-site according to the functional requirements. The shift aspect, outcome signals, hysteresis, problem opportunity, etc., are some functionalities that can be readjusted by the individual depending on the demands.

Digital stress changes are appropriate for computerized and regulated equipment bodies that require programmable features, electronic display screens, adaptability, reliability, entrance protection, and security. Physique 3 is an instance of a power pressure switch.

Functioning principle

The pressure switch in the picture is an example of a solitary post dual toss (SPDT) change, which has a mechanical operation concept. Each component is inside the change case (F), and it also possesses one inlet stress slot (H). Simply put, the inlet tension presses a piston (D) against a spring (C) that keeps a well-known insusceptible force. At that point, the piston sets off the micro-switch (A). It relocates in between the generally closed (NC) and the typically open (NO) opening through an operating pin (B) and a protected journey button (E).

Amount 4: The parts of a pressure switch consist of a micro-switch (A), running pin (B), the assortment spring season (C), working engine (D), insulated trip switch (E), button scenario (F), excursion setting freak (G), inlet pressure (H).

To set the tension fix with the micro-switch buttons between NC and NO, the trip-setting nut (G) changes the spring season wallet deepness. This deepness improvement enables the spring immune force to raise or even lessen, which associates with established stress to trigger the micro-switch. The inlet pressure (H) exerts tension upon the operating engine (D), producing a force resisting the variation springtime (C). When the inlet piston’s pressure is higher than the resisting springtime pressure, it drives the operating pin (B) into the protected excursion switch (E). This button moves the micro-switch from the NC position to the NO placement. If the tension reduces below the springtime pressure, the switch, pin, and piston relocate out of the micro-switch, breaking the link. At that point, the relationship goes from the NO posture to the NC setting.

Choice requirements

Think about complying with option criteria for your use

- Type of media: The media must be compatible with the casing and the tape component.

Nitrile butadiene rubber (NBR) is appropriate for use along with sky and hydraulic/machine oil. Ethylene propylene diene monomer rubber (EPDM) appropriates when water is the channel. Usual media utilized with tension buttons are actually:

- Hydraulic oil.

- Home heating oil.

- Turpentine.

- Petrol/gasoline.

- Air.

- Water.

1.Pressure: It must have the ability to endure maximum functioning stress. A diaphragm design works effectively for suction and also low-pressure uses. For high-pressure requests, utilize a piston design.

2.Temp: It should have the ability to operate effectively within its maximum and minimum temperature level selection.

3.Repeatability: Repeatability, or the accuracy, is the capacity of the tool to efficiently switch back to the same set factor for every repetition. The stability of precision demanded will identify the collection of the pressure switch for your function. Birth control concepts typically give a lot more reliability than the engine style.

4.Hysteresis: Hysteresis is the distinction between the change point and the reset aspect. The change keeps active for an extended period if the reset factor is enormous. If the reset point is concise, the switch will frequently flip between the on/off state. Hysteresis is configurable in a power pressure switch yet preset due to the supplier’s mechanical pressure switch.

Sort of pressure switch: For low pressure and suction applications, use one with a birth control design. For stressful uses, utilize one along with an engine design.

- Commendations: Our pressure switches are ATEX areas 1, 2, and 22, accredited for usage in a potentially eruptive environment.

Electric or even technical pressure switch: A power pressure switch is much more costly yet includes additional command over the setups, like tension setpoint and hysteresis, compared to a mechanical pressure switch.

Common uses

A pressure switch could be made use of in a vast array of residential and also commercial treatments as listed below:

- A/C, gas cylinders, air pumps, and so on usage sky compressor tension switches over to observe and manage the system’s atmospheric pressure.

- Engines use oil tension changes as an actuator or sensing unit to calculate when the engine’s oil pressure has dropped below the preset level.

- Furnace stress changes act as protection units for commercial along with noncommercial objectives. They spot the adverse stress during the heater startup and turn off the heating system with reduced atmospheric pressure.

- Effectively push stress changes are used in noncommercial and commercial structures to carry water from the well and guarantee that there suffices water pressure in the system to offer water without being over-pressurized.

- Water pump tension switches over in domestic, commercial, and agricultural applications to auto-regulate water flow.

- Suction stress shifts method suction or even lousy pressure in the system. They remain in home boilers, electric heaters, sky converters, and transmission bodies.

FAQ

Q: Exactly how to adjust a pressure switch?

A: For a technical pressure switch, shift the almond right to improve and counterclockwise to minimize the switch point. An electric pressure switch has a keypad for modifications.

Q: Exactly how to check a pressure switch?

A: Disconnect electric power coming from the pressure switch and hook up the multimeter to its terminals. The multimeter should go through the public circuit for a usually available control. Activate the course to permit the fluid stress into the pressure switch. If the multimeter performs not review 0 ohms, replace the change. Opposite for a generally sealed switch.

Q: What does a pressure switch perform?

A: A pressure switch monitors the system’s liquid tension and either opens or shuts a power link based on a predetermined pressure amount.

Q: How to inform if a pressure switch misbehaves?

A: The pressure switch can possess problems if the liquid is leaking, the pressure is also low, tension changes often, and incorrect preliminary collection pressure.

Q: Strictly, how carries out a mechanical pressure switch work?

A: When the inlet requirement force is above the spring’s pre-tensioned point, it shifts the electric call. An NC get in touch with will open, and an NO call will shut. When the stress decreases, the calls return to their typical state.

Q: What is the variation between a pressure switch and a tension sensor?

A: Tension switches overwork electric switches at a preset pressure level, while pressure sensors read the system stress and turn it into an electric indicator.

A pressure switch is a tool that works a power to get in touch with when a predetermined liquid pressure is connected. The change creates an electrical call on either tension rise or pressure loss from a predetermined pressure level.

A technical pressure switch uses a spring season and a diaphragm, or engine, to handle at what pressure the micro-switch is induced. Hysteresis is configurable in an electric pressure switch but pre-programmed through the supplier in a mechanical pressure switch. Transform the circuit to allow the liquid tension into the pressure switch.

Why choose Unionwell pressure switch China manufacturer?

Huizhou Unionwell Sensing & Control Electronics Co., Ltd specializes in producing quality micro switches for the automotive industry and white goods of home appliances. Main products include basic micro switches, waterproof switches, air pressure switches, mechanical keyboard switches, and door switches.

For better pricing, lead time, and quality control guarantees, we acquired Huizhou Greetech Electronics Co., Ltd in 2021. We made it our China production base with over 500 employees and a 250 million pieces/year production capacity.

With the subsidiary sales branch Guangzhou Unionwell Sensing & Control Technology Co., Ltd founded, our global reach covers North America, Europe, Asia, and South America.

Most of our business partners/end customers are Global 500 enterprises, including world-famous home appliance brands and leading automotive suppliers in North America and Europe.

We are launching a new industrial base at Longmen, Huizhou, Guangdong Province, which will work as Unionwell headquarters. Automation equipment will be introduced, massively improving the switch production capacity from 250 million pieces to over 1.3 billion pieces/year.

For more micro switches, please visit our official website.

https://www.unionwellswitch.com/

Or send an email: inquiry@unionwellswitch.com