Micro Switch Types Introduce

Today, Let’s learn the micro switch types introduce!

Small micro switches have become an indispensable portion of the picking up and command neighborhood, whether in the commercial, development, farming, industrial, or even transit sector. There are possibly trillions of tiny buttons to use at this instant in numerous sorts of commercial tools, farming or even building machines, and command systems around the globe. The truth is that such an essential device– with commonly available or even closed connections combined with a snap-action changing mechanism– is competent in executing at an improved precision degree, dependably and suitably, in the numerous severe settings merely surprising.

What is a micro switch?

A microswitch is a snap-action preciseness transition button and a tiny contact void. The snap-action determines a conversion switch whereby connection creation and breaking velocity are the individuals of the operating speed of the actuator. It is additionally described as a small snap-action button.

Matched up to regular changes, mini buttons have the observing distinguishing characteristics:

- Lowered dimension.

- Lessened operating traveling: tenths of a millimeter.

- Raised electrical residential properties.

- Increased life span.

- Reduced sensitivity to vibrations as well as higher velocities.

Microswitches are usually the ideal fit for visibility and lack detection where bodily exchange of an item is allowable. They likewise succeed in applications calling for straightforward on-and-off activities. Each switch contains a springtime and a set of contacts that change power on an actuator/plunger into an electric outcome.

These switches are ideal where sparing room and body weight are essential.

Unionwell G5 Series Basic Micro Switch Products List >>

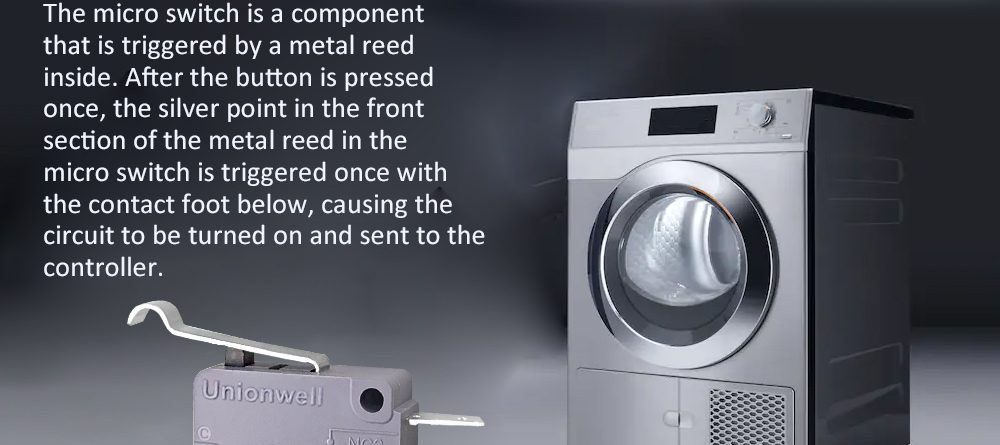

How carries out a micro switch job?

The micro switch creates a physical exchange of an item. After that, its contacts modify location.

The simple operating guideline is as follows:

When the plunger is in the discharged or rest opening

- The typically finalized circuit can bring present.

- The ordinarily open course is electrically insulated.

When the bettor is actually miserable or even changed

- The usually finalized circuit is available.

- The ordinarily open circuit is closed.

Building and construction of a micro switch

The building and construction of a micro switch are accessible. The significant parts of the controller are:

1. Plunger (Actuator).

2. Cover.

3. Moving item.

4. Support.

5. Scenario.

6. NO terminal.

7. N.C. terminal.

8. Call.

9. Relocating upper arm.

Types of mini buttons.

Micro changes possess various kinds. Some of all of them are listed here:

1-Pin bettor.

Suited for short straight movements, switch characteristics are used directly, and high-precision placement diagnosis is also feasible. The overtravel, however, is the quickest of any actuator, calling for a trusted stopper.

2-Spring pin bettor.

Overtravel is much longer than for a pin bettor. However, the same function approaches are achievable. The bettor dimension is somewhat more significant, but off-center loads have to be stayed clear of, i.e., the tons should get on the center of the bettor.

3-Spring quick pin bettor.

Overtravel is large, just like for a springtime pin bettor. The bettor is short and possesses a larger dimension to create placement simpler.

4-Panel install pin bettor.

The overtravel is the most extensive of all bettor styles. They are positioned to a panel utilizing a hexagonal nut and locknut (the placing position can easily be readjusted by readjusting the almonds). The plunger may be run either by hand or even mechanically, and use in combination with a low-speed camera is also achievable.

5-Panel placed (cross) roller pin bettor.

A curler is connected to a board, placed pin plunger button, and is worked along with a webcam or even a dog. The mounting posture may be adjusted like a board mount pin bettor button, but the overtravel is slightly smaller. Cross curlers are additionally available that operate parallel to the change.

6-Leaf spring season.

The stroke is much more significant due to a powerful fallen leave spring, producing this actuator suited for low-speed cams or cylindrical tube travels. The bearing factor is dealt with, so the overtravel needs to be kept within standards in the treatment to avoid damage.

7-Roller leaf springtime.

A leaf spring season actuator with a curler fastened. Ideal for camera or even canine procedure.

8-Leaf bar.

A bend in the bar is used to produce a sizable movement. Suitable for recognizing pets, cams, and numerous other relocating objects.

9-Simulated roller leaf lever.

A fallen leave bar with completion arched right into a contour to enable treatment as a specific curler type.

10-Hinge lever.

Utilized along with a low-speed, low-torque camera, the amount could be changed to match the operating body system. Steel is primarily used as the material for the bar.

11-Simulated curler lever

A hinged lever with completion angled into a curve, enabling application as a simple roller kind.

12-Hinge curler bar.

A hinged lever with a curler affixed. Ideal for high-speed webcam procedure.

13-Reverse operation joint bar.

Utilized along with a low-speed, low-torque webcam, the shape of the amount may be altered to match the operating body. Steel is primarily used as the component for the lever.

14-Reverse procedure joint curler bar.

A reverse procedure hinge bar and a roller fastened—ideal for webcam function.

15-Rotating operation.

A low-torque actuator along with a spinning operation. They are suited for recognizing the light in weight items, such as pieces and newspaper currency.

16-Flexible pole.

The functioning force is tiny. The overtravel is soaked up through the actuator, delivering a sizable allowance in procedure object play.

Interpretations of operating features.

The meanings below reveal the significance of operating features. Designs demonstrate how attributes are measured for in-line bettor actuation. Linear dimensions for in-line actuation are from the leading of the bettor to a source line, typically the center of the placing holes.

Differential Travel (D.T.).

Bettor or actuator travels from where contacts” snap-over” to aim where they” snapback.

Free Position (F.P.).

A button bettor or actuator is placed when no external force is administered (other than gravitation).

Total Overtravel Force.

The pressure is needed to accomplish the total overtravel of the actuator.

Operating Position (O.P.).

Role of button plunger or actuator after that contacts snap from usual to working. Note that inflexible or flexible actuators, the operating position is measured from the completion of the lever or even its optimum span.

Working Force (O.F.).

The pressure-volume changes the bettor or actuator to trigger called” snap-over.” Keep in mind that in the scenario of adjustable actuators, the power is measured from the maximum length job of the bar.

Overtravel (O.T.).

Bettor or even actuator trip carefully accessible beyond the functioning job.

Pretravel (P.T.).

Range or angle traveled in relocating plunger or actuator from free position to functioning position.

Launch Force (R.F.).

Quantity of force is still related to switching over bettor or even actuator when calls pop from run stance to unoperated position.

Total Travel (T.T.).

Span was coming from complimentary actuator placement to overtravel limit setting.

Mounting of mini switches.

Side positioning buttons must be placed on smooth, firm, level surface areas using the encouraged screw dimension. Stay away from over-tightening the screws. For incorporated safety, they should be locked using the epoxy substance. Do not seek to enlarge switch mounting gaps or steer clear of over-stressing the switch. Use protecting material between the switch and metal platters to enhance clearance on changes with available terminals.

When soldering, heating up of the button insulation has to be avoided. In particular situations, it may be recommended to use a heat shunt. For optimal mechanical strength, the conductor must be covered around the pointer of the incurable taking treatment to stay clear of loose hairs of the cord.

Micro switch applications.

Microswitches may be utilized for a broad series of electrical bunches and functioning power in higher cost-of-failure prospective applications like Devices, timing units, workplace equipment, pc/ business tools, examination devices, personally worked tools, as well as valves. Vending equipment, water heater, and also industrial management.

HVAC wall management, automotive, truck, and boat cable harnesses lock modules for tail-gate/ trunk, sub-assemblies for flexible roofing systems, and shoe pedal managements. Aerospace, instrumentation, workplace equipment, medical/dental devices, and much more.

A microswitch is a snap-action preciseness alteration button with a tiny connection gap. A roller is connected to a board position pin plunger change and is worked with a webcam or even a pet dog. The placing setting may be changed the same as a boarding place pin plunger button. However, the overtravel is slightly much smaller. Do not attempt to expand switch mounting openings and stay away from over-stressing the switch—use insulating material between the change and metallic platters to enhance space on switches and available terminals.