Factors That Affect The Quality Of The Micro Switch

The components that determine the microswitch’s quality are the protection, weldability, conduction reliability, life, feel, production process, and installation dimensions of the power switch. In addition, the critical factor that determines the life of the shrapnel is stamping technology. Japan and Taiwan’s stamping technology is already very popular in the country, so in the case of technological improvement, the requirements for imported materials are reduced. For example, the life of 160gf shrapnel in the market is mainly about 50,000 times (domestic phosphor bronze or relatively backward stamping technology), about 100,000 times, and more than 200,000 times (stainless steel). The fourth is the production process.

After accessories are available, the assembly process affects the quality. The assembly process depends on factors such as the management ability of the production company, staff quality awareness, and quality assurance capabilities. The quality of products with different assurance capabilities must be different.

The market assembly methods include labor and machinery, and the assembly cost is low. However, the product quality is low, the manual assembly cost is high, and the quality is also high. The fifth is the factory inspection.

Methods And Items Affect The Quality Of The Microswitch

The factory inspection methods and items also affect the microswitch’s quality. Whether the appearance, feel, continuity, resistance, and other items are random inspection or full inspection, for example, the scrap rate required by some large factories is measured by PPM. If there are no defects or zero defects, it is necessary to set up random inspections, or quality inspections after the factory inspection are set up for full inspection. In micro switch electronic components, an insert molding process is often used to enhance the strength and rigidity of the metal terminal.

The base of the microswitch is a typical example. The size of the tiny micro switch is usually about 10mm, and some even about 5mm. The thickness of the reed is about 0.1mm. The cantilever before the injection is long and easy to deform. Therefore, using plastic as the base body, preload the reed into the mold cavity before forming. The molten material and the reed are combined and solidified to form a metal-plastic integrated product.

The plastic base supports the strength of the reed. Have been greatly improved. Due to the small size of the micro switch and the relatively complicated production process, automated production is generally adopted to improve the quality of the parts and the production efficiency. Therefore, rationally designing the production process and innovatively designing the mold structure is significant to ensure the quality of the parts and reduce the production cost.

The Micro Switch Function

The micro switch is mainly used to switch on or off the circuit by turning the handle to achieve the circuit’s purpose. It is generally used in low-voltage circuits and has the characteristics of flexible action and stable and reliable performance.

The micro switch is generally a tiny current switch. The rated power is 0.1A, 125/250VAC; the operating temperature range is -40℃~+85℃. The manufacturing process requires that the microswitch is mainly formed by performing the corresponding process treatment and assembly on each component. The shell is processed through nickel plating or blackening to prevent oxidation. Fretting can usually break the current from 5mA/5VDC to 25A/250VAC.

The micro switch product line provides products from low energy consumption to power load electrical type, suitable for various applications.

Unionwell G304 Series Micro Switch Products List >>

Micro Switch Environmental Requirements

Engineers must know the rated current and voltage (AC or DC) required to select the appropriate switch for a specific application. Since various devices in all industries are committed to low energy consumption, the micro switch must work under low current (logic level load) and DC voltage.

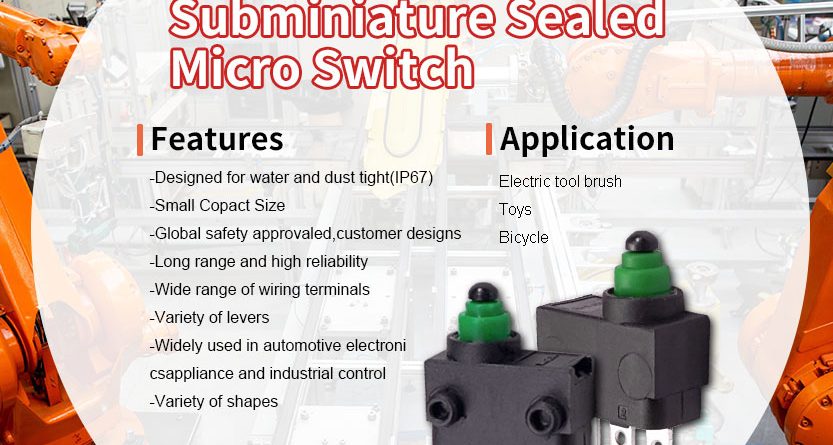

Environmental requirements greatly influence the micro-switch selection, especially in applications requiring high reliability and criticality, such as industrial control and medical equipment. Understand the environmental conditions of the application, including pollutants in the air that may enter the switch, the liquid in which the switch is located, and operating temperature requirements.

When buying a micro switch, choosing a switch that meets various international electrical requirements can help you simplify product design for different regions. Some major standard certifications include UL certification in the United States, CUL certification or CSA certification in Canada, ENEC certification in Europe, and CQC certification in China.

Huizhou Unionwell Sensing & Control Electronics Co., Ltd

Huizhou Unionwell Sensing & Control Electronics Co., Ltd is committed to producing all kinds of waterproof micro switches, sealed micro switches, Auto micro switches, micro switches, basic micro switches, and detection switches.

As a professional micro switch factory in China, we have established long-term cooperative relationships with world-renowned automotive and home appliance customers.

Welcome to our website to learn more about the microswitch: https://www.unionwellswitch.com or https://www.greetech-switch.com