Choosing Microswitches Need 5 Key Steps

Since the microswitch’s introduction in the 1930s, small electromechanical microswitches, such as micro switches, have evolved to meet various application requirements, including aerospace, home appliances, boiler controls, medical equipment, and sprinkler systems, test equipment, timers, and vending machines. People use micro switches to detect temperature, position, and liquid level.

Precision micro switches generally have three primary types, operating handle, and shell-type specifications. Some microswitches use a push and spring design. Whether factory engineers are looking for a thermostat for residential heating or industrial boiler control, or a level switch for a large oil tank, there are five key characteristics to consider:

- Dimensions

- Electrical requirements (voltage/current)

- Reliability (mechanical/electrical life)

- Environmental factors (hazardous environments, temperature ranges)

- Agency approvals

Here are five key steps to help you choose the suitable microswitch for your specific application

Step 1 Understand how switching form factors affect other characteristics.

Switches size matters when choosing a micro switch. Switch size is directly related to its current range, travel, and operating force. For example, one of the smallest microswitches on the market today measures 0.50″ x 0.236″ x 0.197″ (LxWxH). While this tiny switch is suitable for detecting circuit conditions in compact circuit breakers, it typically only interrupts 0.1 to 3 amps (A) and has a short stroke.

Applications that require higher currents require larger switches. For example, the micro switch that detects the liquid level in a fuel tank application must provide a large stroke and withstand a large current. Usually, the switch drives the pump in level switch applications and carries a large current. This working environment requires a large microswitch rated at 20A or 25A at 125VAC or 250VAC.

Tip: The smaller the switch size, the smaller the travel and the interrupted current. In addition, the external size of the switch also affects the operating force. Ideally, engineers need a switch with a low operating force and high current capacity. But in fact, a compromise is required between these two parameters.

Microswitches maintain good contact while providing an extensive current-carrying range. The micro switch requires a stronger spring, increasing the switch’s operating force and size. Operating forces can range from 2 grams in pressurized air-type applications to 8 ounces in solenoid valve applications (where higher operating forces are required). One of the most significant switches on the market measures 1.94″x0.69″x1.3″ (LxWxH).

Engineers should also pay attention to the differential travel of the switch—the distance between the switch’s tripped position and its reset position. Its threshold will vary according to different applications. For example, in temperature switch applications, the on/off operating points should be as close as possible, and the differential travel should be as low as 0.0001 inches. However, applying a liquid level pump may cause the make-up pump to start and stop too frequently, shortening the pump’s service life if the differential stroke is too close.

Step 2 Know your electrical requirements.

Microswitches are typically capable of breaking currents from 5mA/5VDC to 25A/250VAC. The Micro Switch product line offers a range of products from low energy consumption to power load electrical types for various applications. Engineers must know the current and voltage ratings (AC or DC) required to select the appropriate switch for a specific application.

As all kinds of devices in all industries strive for low energy consumption, microswitches must operate at low currents (logic level loads) and DC voltage. However, some applications require switches that break high currents and voltages, such as industrial-grade pump applications. In addition to load requirements, engineers must also select the appropriate circuit.

The switch contacts must be normally open (NO) and normally closed (NC). For NO type contacts, usually, no current flows between the contacts. The contacts are closed when the switch is actuated and connected. For NC-type contacts, there is usually a current flow between the contacts. The contacts are opened when the switch is actuated, and the circuit is disconnected.

Step 3 Consider environmental conditions.

Environmental requirements greatly influence the selection of microswitches, especially in applications requiring high reliability and criticality, such as industrial control and medical equipment. Understand the environmental conditions of the application, including contaminants in the air that may enter the switch, the liquid in which the switch is located, and operating temperature requirements.

You must choose a sealed switch with a wide operating temperature range for applications in harsh environmental conditions. Highly reliable microswitches can operate from -65 degrees Fahrenheit (-54 degrees Celsius) to 350 degrees Fahrenheit (177 degrees Celsius) for various applications. At the same time, You must note that the degree of protection of the switch should be at least IP67 to prevent liquid intrusion. The switches’ function eliminates the need to spend a lot of time designing an enclosure that achieves the same degree of protection.

Step 4 Clarify working life requirements.

Switch reliability is critical.

It would be best to determine how much electrical and mechanical operating life an application needs.

Different switches have different contact materials, housings, and terminals to meet different applications’ electrical and mechanical life requirements.

A highly reliable microswitch can operate 10 million to 20 million times before mechanical failure and 50,000 to 100,000 times at maximum load before electrical failure. As for the slight price difference between different quality switches, you need to consider the total use cost. Because you’re not only paying for the switch, you’re also paying for the long-term, trouble-free operation of the switch. In many cases, the additional cost of using a more reliable switch is offset by a lower warranty cost during use.

Step 5 Check Agency Accreditation Requirements

Choosing switches, which meet various international electrical requirements, can help you simplify product design for different regions. Major standard certifications include UL certification in the United States, CUL certification or CSA certification in Canada, ENEC certification in Europe, and CQC certification in China.

When choosing a snap action micro switch, you need to consider multiple factors, such as form factor, load requirements, operating environment, and reliability, so it is essential to understand the actual application requirements:

- What size switch is required?

- What is the required power rating?

- Is it a low voltage application?

- Does the switch need to be sealed?

- Does the switch need to withstand extreme temperatures?

- Does it need international certification?

Why Choose Unionwell Micro Switch China Manufacturer?

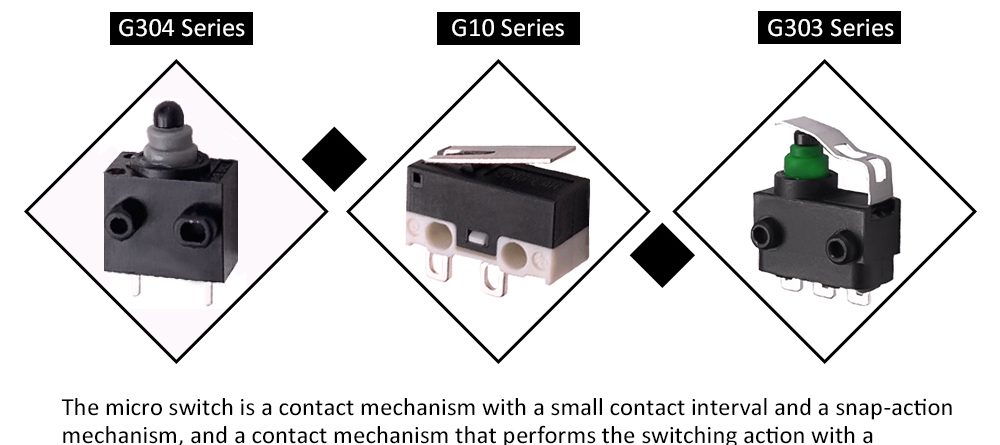

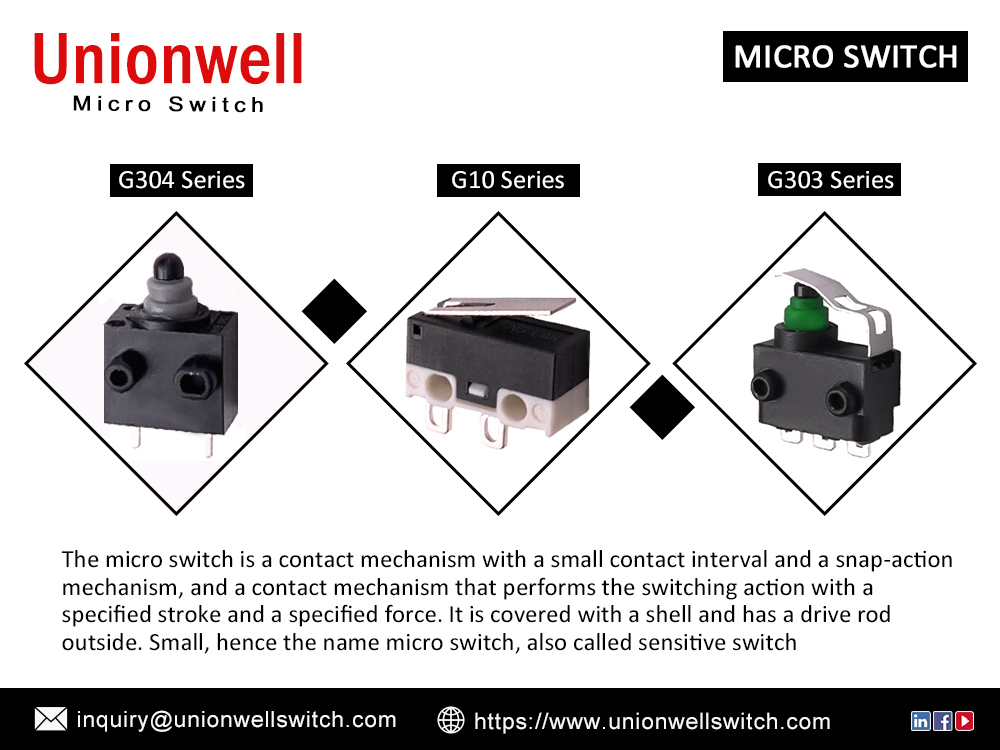

Unionwell’s micro switch product series has basic microswitch, waterproof switches, rotary switches, rocker switches, etc.

The micro switches have UL, ENEC, CQC, and other certifications. The factory has passed ISO9001, IATF16949, and ISO14001 quality system guarantees.

Unionwell G3 Series Subminiature Sealed Micro Switch Products List >>

Our micro switches are widely used in home appliances, electronic equipment, automatic machines, communication equipment, car electron, apparatus and instrument, electric motion tool, etc. For more micro switches, please visit our official website:

https://www.unionwellswitch.com/

Need more unionwell microswitch about price and inventory? Please send an email:

inquiry@unionwellswitch.com