2 Ways To Reduce The Loss Of Micro Switch

First, increasing the contact element’s surface strength is the primary means of slowing the loss. It undergoes various surface treatments, such as physical (laser, ion implantation, etc.), chemical (carburizing, nitriding, and other surface hardening techniques), mechanical (blasting, rolling, etc.), and enhanced surface residual compressive stress.

The process method gives the material’s surface a unique composition, texture, and properties for improving its wear and fatigue resistance. In addition, there are ways to enhance the electrical capacity of the fragile metal reeds and contacts, such as replacing metal materials such as silver and alloy.

Second, Structural design changes can also reduce the loss. Changing the internal geometry of the component, clamping mode, contact size, etc., and the pressure distribution and contact mode at the contact surface can improve the performance of anti-fault damage to varying degrees.

Another effective measure to slow down the fretting loss is reducing friction coefficient (i.e., friction), which can be achieved by adding a lubricant.

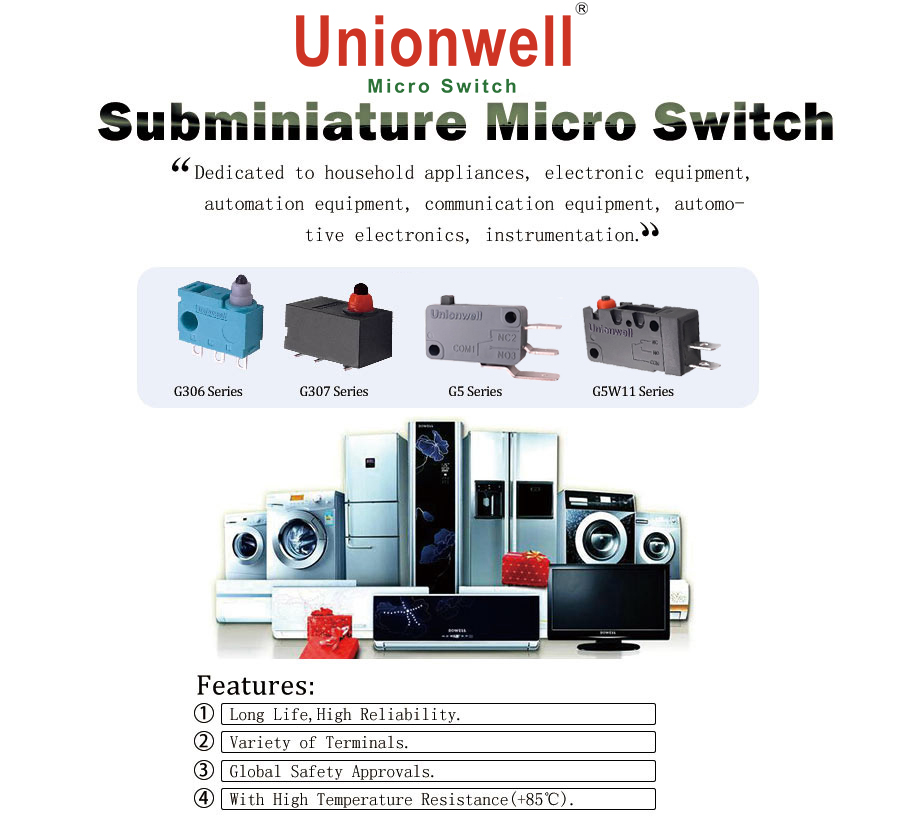

Unionwell switches manufacturing various micro switch, basic subminiature switch, basic switch, etc., and has a one-stop R & D and production system. Our website:www.unionwellswitch.com.